Over the past years, the pharmaceutical industry has met new legal requirements for safety and quality of their products. In accordance with EU FMD regulations, serialization is now a mandatory requirement which the manufacturers of pharmaceutical products must comply with so that all customers within the EU are guaranteed authenticity and quality of their prescription medicinal products. On a global scale, however, several markets have greater demands regarding quality and security than serialization alone. If companies want to maintain a worldwide client base and brand themselves on their credibility, reliability and quality, they must, in addition to serialization, be able to aggregate their products, i.e., make their products traceable in the supply chain and thus quality assured.

For many years, Multicheck has been one of the pharmaceutical industry’s preferred suppliers of Track & Trace solutions from WIPOTEC-OCS. With their serialization and aggregation equipment, WIPOTEC-OCS has one of the industry’s best safety systems against falsified medicines and other pharmaceutical products. Since 2019, GMPack has serialized and aggregated large parts of their products which means that they have implemented the industry’s safest and most reliable quality and safety control.

The collaboration between GMPack and Multicheck began in 2017 when GMPack needed a vendor to provide them with Track & Trace solutions containing built-in serialization and aggregation. At that time, the EU FMD regulations had already been adopted, but serialization was not yet a requirement. Nevertheless, GMPack wanted to be abreast of the forthcoming regulations and thus make serialization and aggregation key components in their production. This was partly due to the fact that GMPack at that time had just established contact to a major European customer who was interested in having GMPack’s packaging facility handle the packaging of their pharmaceutical products for the Russian market. GMPack had to guarantee the European customer serialization and aggregation, as both were requirements in Russia per. July 1, 2020. Multicheck’s implementation therefore had to happen through two phases: Firstly, serialization had to be implemented so that GMPack would be able to produce their products in accordance with FMD regulations and trade within the EU. Secondly, aggregation had to follow the same process. Our sales team at Multicheck, led by Product Manager Kristian Johansen, therefore had to analyze the GMPacks production in Hadsund in order to put together the best solution for their specific needs and wishes. In the late summer of 2018, we were able to present our final proposed solution to the factory manager and part owner of GMPack, Christian Kjærgaard.

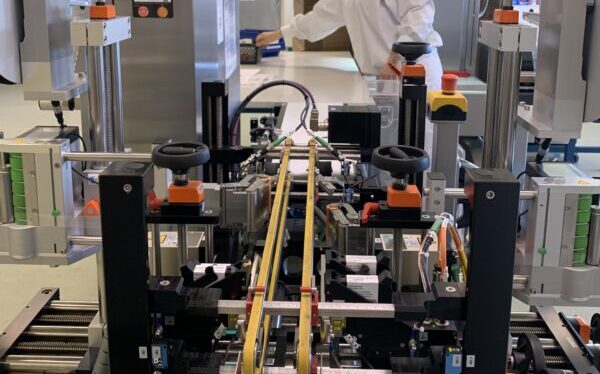

As a solution the need for serialization, we chose TQS-SP-TE (Traceable Quality System) from WIPOTEC-OCS. Our service team ran a series of tests on GMPack’s products, and it quickly became apparent to both parties that TQS-SP-TE was the ideal addition to the production line. One of the demands for our proposed solution was that the system should be able to serialize boxes of different sizes and secure the boxes with Tamper Evident since many boxes of different sizes run through their packaging facility on a daily basis. As Multicheck was able to supply TQS-SP-TE with the option of step-less adjustment for almost all formats as well as providing additional safety with Tamper Evident, it was, with the addition of TQS-SP-TE, now possible for GMPack to serialize the specific boxes in accordance with their individual measurements in an easy, swift and safe manner.

It was of the highest importance to GMPack that we could find a solution that did not require major changes in their existing production environment. In other words, Multicheck had to present a proposed solution that would be compatible to GMPack’s established line of packaging in the production. TQS-SP-TE can be installed in a line with an automated product flow and as a mobile stand-alone unit with a manual supply. The model thus met all of GMPack’s requirements, and shortly hereafter, Service Engineer Kenneth Feldt installed the TQS-SP-TE as a new element in their quality control. Mr. Feldt was also in charge of the introduction training. Since the completion of installation and training in the autumn of 2018, GMPack has been able to serialize with the industry’s best technology by optimizing their productivity and product quality, hereby complying with the EU FMD regulations.

After a while, when the serialization had run smoothly and with satisfying results, Multicheck began the next phase of the collaboration with GMPack. In line with the promise GMPack had made to its European customer, we implemented TQS-CP from WIPOTEC-OCS as a solution the need for aggregation. TQS-CP is characterized by its user-friendliness, the new technology and its ergonomic design. The operation takes place without any difficulty: The operator places the packaged cases manually in layers within the box, whereupon the high-resolution camera automatically places itself in the correct focal distance and records all serial numbers layer by layer until the box is full. After this, the aggregation level will be completed for the box in question, and it will be placed upon the pallet. Once all boxes are scanned, the aggregation of the pallet is completed with a label containing all the exact information about the shipment, as well as a report and an encrypted file, which is uploaded unto GMPack’s ERP system.

Thus, with TQS-CP, Multicheck was able to offer GMPack an all-in-one solution, combing easy and swift product managing with safe and reliable aggregation of each product. Since we delivered TQS-CP in the winter of 2019, it has, along with its partner ‘TQS-SP’, been an important part of the fact that GMPack today is able to perform the safest and most reliable safety control in the industry.

Overall, the collaboration between Multicheck and GMPack has been a huge success. GMPack is now, with their high-quality standards, able to distinguish themselves from other packaging facilities. Factory manager and part owner of GMPack, Christian Kjærgaard, said: “The collaboration with Multicheck has meant a lot to us. We have had a good and constructive dialog from moment one. Kristian and the rest of the team have been well-prepared and professional. The impression has been good from the beginning.” He added: “As our packaging facility is now able to serialize and aggregate, we can offer a safety control that is different from that of other packaging facilities. This means that we have become way more efficient with the addition of aggregation. We can now optimize our product in the markets, where we are already represented, and take up new ones, where the safety protocols are different. Our collaboration with the large European costumer is a perfect example of this. We look forward to continuing our collaboration with Multicheck in the future.”